No products in the basket.

Mechanical Threaded Bolts and Nuts are the Fastener of choice across many Industries due to their strength characteristics as well as their ease of assembly.

The ease of assembly also means they can be vulnerable to self-loosening and loss of Clamp load in certain applications and conditions if the joint is not secured.

Maintaining the “Clamp Load” in the joint, often referred to as the “Pre-Load” is critical to stop the self-loosening of fasteners.

The simplest way to look at a fastener is to view it as a very stiff spring. When the head of the fastener is held in place and you tighten a nut down its length you are stretching the length of the bolt which creates tension in the axial direction (Its length). The opposite reaction to this is what we call the Pre-Load or Clamping Force, this is generate by the bolt trying to return to its original length. This only works within the elastic limit of the bolt (where it will return to its original dimension) so the trick is to design the connection with enough Pre-load to hold the joint together but without taking the bolt into permanent deformation.

The loosening of Fasteners is generally caused by a few factors such as Vibration, Dynamic Loading, Shock, Creep and or relaxation.

However, even with the most complex of calculations and efforts to design the correct bolted joint some of these factors can contribute to it self loosening which may or may not be known at the design stage.

The loosening of a nut and bolt can be frustrating especially if it is in an environment where you can see it happening and it requires re-tightening but in some applications it is much more critical and a loose fastener can equate to a catastrophic failure of the joint which can be extremely dangerous leading to potential hazards and also down time for equipment.

The trick is to try and maintain the pre-load in the joint at all times. The Junker test was developed to show and test how different devices performed under joint movement. The test was a pioneering experimental research into the behaviour of bolted joints under transverse loads, conducted by German engineer Gerhard Junker in the late 1960s which underpins modern theories on self-loosening behaviour. The test today is to DIN 25201 and is used across many industries as the overall standard to test for the self-loosening of nuts and bolts worldwide.

We have developed a video to show how traditional nuts and bolts without any additional security devices perform under this testing as well as how effective these devices are. The securing of nuts and bolts has been an issue dating back to the very first applications where dynamic loads and vibrations would work them loose so we still have some of the traditional solutions available today.

It only takes a few hundred cycles for the majority of the load to be lost and eventually the joint comes completely loose without any securing devices.

Over the years many devices have been developed to try and maintain the pre-load but the majority of them do not succeed in maintaining the levels of load required for the joint to function as it was deigned to.

Most devices work on a Friction based system that grips onto the thread by either introducing a material such as nylon or by distorting the thread to create what is known as pre-vailing torque so that it grips harder to the thread than a standard free running nut. The problem with these solutions are:

1 The ease of installation is taken away because they require more effort to install

2 The effectiveness of using a lubricant is eliminated because they rely on friction

3 They can still rotate a small amount and it only takes around ¼ of a turn anti-clockwise and you lose most of the load in the joint

In our video The Nylon inserted nut and all Metal Locking nut maintains upto 30% of the original pre-load in the joint over the 2000 cycles but this will gradually reduce over further cycles when the nut backs off further.

Another common and traditional product known as the Spring or Split Washer is often used to try and solve this common issue. The theory behind this is that it increases the tension in the joint but in practice this is not the case. The spring / split washer has no locking function and in the worst-case scenario it actually has the opposite effect and forces the nut off.

The danger with both this product and the friction-based products are they often will maintain a very low amount of pre-load which cannot be untightened by hand and is therefore potentially more dangerous because the joint will be moving around and could be subject to a catastrophic failure if not maintained correctly.

The solution to all these problems is to use a Wedge Locking washer

The simplest ideas are often the best and this is certainly one of those.

The Wedge Locking washer works purely on Geometry. It comes as a pair of washers in two halves which are glued together for assembly purposes only. It essentially acts as one washer maintaining the speed of installation you would get from a standard washer and free running nut and bolt.

The washer is installed underneath the nut like a standard washer would be and also underneath the bolt head if you have a through bolted joint. The fastener is tightened up as normal to induce the pre-load (Clamping force) into the joint. This means that lubricants to improve the efficiency of the bolted joint can still be used.

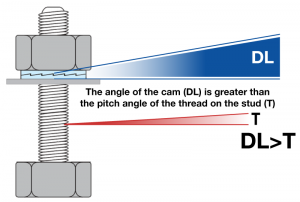

The radial teeth on the outside of both pairs of the washer are made hard so that they bite into the material you are fastening to and to the underside of the nut and bolt head. This positive gripping to the surfaces creates friction at these contact points so that when the fastener tries to untighten it will do so through the middle of the pair of washers that have smooth surfaces. The clever part is that the smooth surfaces include a series of Cams that locate together and have an angle which is slightly steeper than the pitch of the thread.

This means that the Wedge Locking Washers are maintaining the pre-load in the joint by TENSION in the bolt and not FRICTION on the threads. When the connection tries to self-loosen it actually increases the tension very slightly and maintains the load. The only way the joint can be loosened is by applying a physical force with a socket or wrench to force the washers apart and ride over the top of the cams. You will never need to apply a higher force to untighten them making them re-useable and practical for maintenance applications too.

See our video showing this in practice and get in touch with your next bolting challenge and we will do our best to help you find the right solution.